NEWS

ENTESAFETY

Safety Footwear ISO Standard EN ISO 20345

Safety shoes play a crucial role in safeguarding the feet of workers in various industries. The EN ISO 20345 standard, also known as the European Norm for safety footwear, sets the benchmark for the performance and safety requirements of safety shoes.

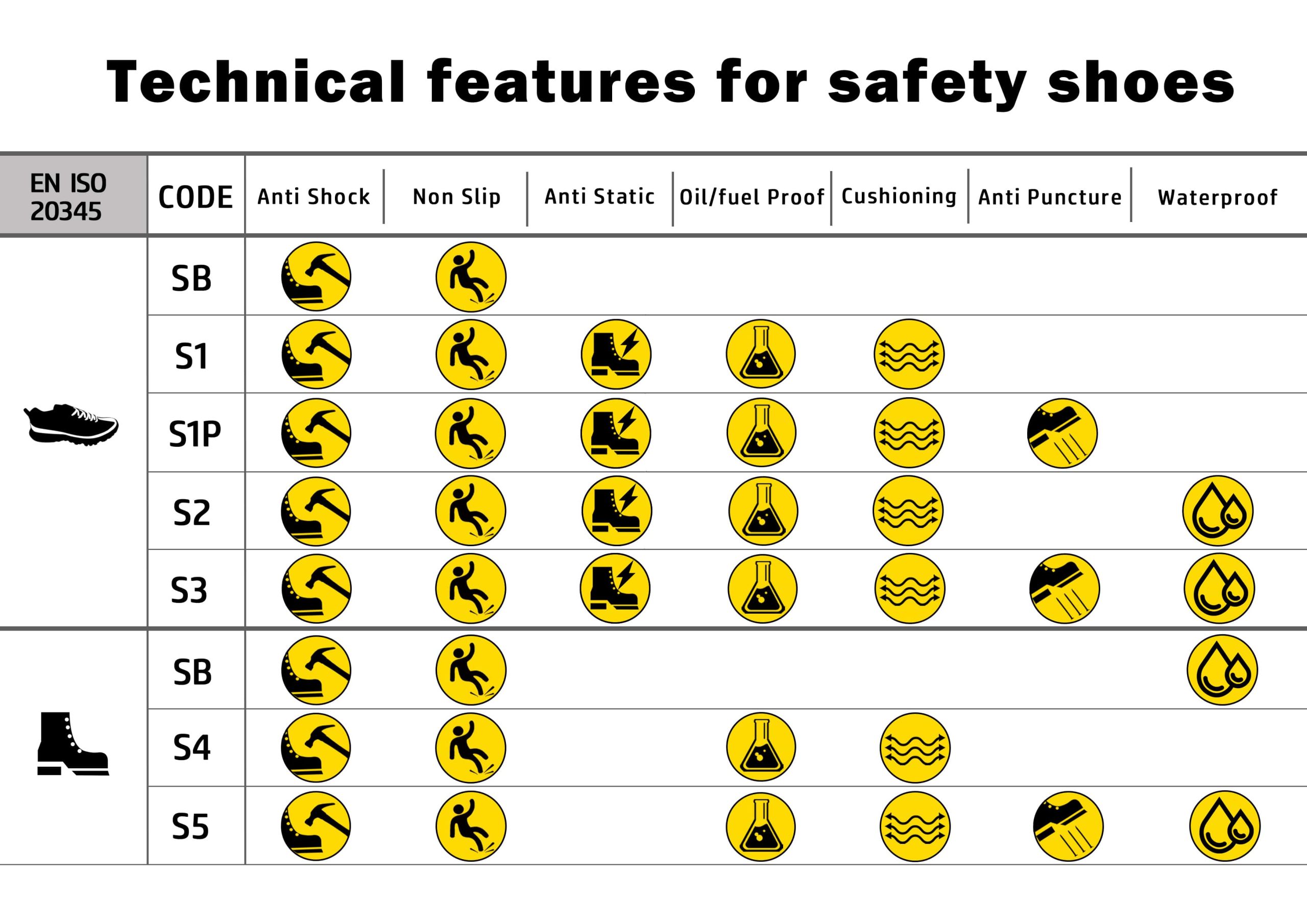

The current safety footwear standard across Europe is updated in 2011 to make it stricter, all products must be manufactured, tested and certified under EN ISO 20345. This safety footwear standard requires all safety shoes to have front foot protection against a 200 joule impact. This is the amount of energy the toe region can absorb before breaking. Under the EN ISO 20345 standard there are different safety classes like S1 or S3 for example. Every safety shoe according to the EN ISO 20345 safety footwear standard will be tested on all possible aspects and will be granted an S-class. In this blog post, we will delve into the key aspects of EN ISO 20345 certification and how it ensures the protection and well-being of workers on the job.

CE EN ISO 20345 : Safety Shoes Standard

Understanding EN ISO 20345

EN ISO 20345 is a widely recognized safety shoe certification standard adopted in Europe and globally. It outlines the minimum requirements for safety footwear, ensuring they meet specific criteria to protect against common workplace hazards. The standard classifies safety footwear into different categories based on their protective features, providing users with an informed choice to meet their specific needs.

Impact and Compression Resistance

One of the fundamental requirements of EN ISO 20345 is to ensure safety shoes provide sufficient impact and compression resistance. This involves testing the footwear’s ability to protect the toes against heavy falling objects and high-pressure forces. Safety shoes are classified into different categories, such as SB, S1, S2, and S3, each offering varying degrees of protection, including steel toe caps, composite materials, and puncture-resistant midsoles.

Slip Resistance

Slip and trip accidents are common in many workplaces, leading to injuries and potential downtime. EN ISO 20345 demands that safety shoes undergo rigorous slip resistance testing. The standard evaluates the shoe’s outsole material and tread pattern to ensure workers have secure footing on various surfaces, reducing the risk of slips and falls.

Electrostatic Discharge (ESD) Protection

Certain work environments, particularly in electronics and manufacturing, require safety shoes with ESD protection. EN ISO 20345 ensures that safety shoes designed for such settings dissipate static electricity safely, preventing damage to sensitive equipment and avoiding the risk of electric shocks to workers.

Water Resistance

In wet or outdoor work environments, keeping feet dry is essential for comfort and preventing various foot-related issues. Safety shoes certified under EN ISO 20345 are tested for water resistance, ensuring they provide a certain level of protection against water penetration.

Ergonomic Design and Comfort

Comfort is a vital factor for workers who spend long hours on their feet. EN ISO 20345 takes ergonomics into account, requiring safety shoes to be comfortable and fit well. Properly designed safety shoes can enhance overall work performance and reduce the risk of fatigue or discomfort.

Labeling and Marking

To ensure easy identification and compliance, safety shoes certified under EN ISO 20345 bear specific labeling and marking. The label includes information such as the manufacturer’s name, product model, classification code, and relevant safety features.

ES003

- Stainless steel midsole plateabove 1100 newtons

- Stainless steel toecap above 200 joules

- The sole has undergone special anti slip treatment and added anti-static materials

- Lightweight knitted fabric upper for breathability and heat resistance

- Soft and comfortable sole for prolonged standing

If you need high-performance safety shoes, don’t hesitate to contact us immediately! info@eternitysafety.com