Safety Shoes for Oil and Gas Industry

NEWS

ENTESAFETY

Safety Shoes for Oil and Gas Industry

When providing safety footwear for the oil and gas industry, choosing the right work shoes is paramount. Workers in this industry often operate in high-risk environments, including liquefied gases, oil rigs, refineries, and chemical plants. To ensure the safety and comfort of employees, the oil and gas sector requires specific types of safety shoes. This article will introduce some safety shoes suitable for the oil and gas industry and recommend a few ideal choices.

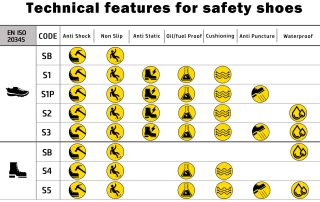

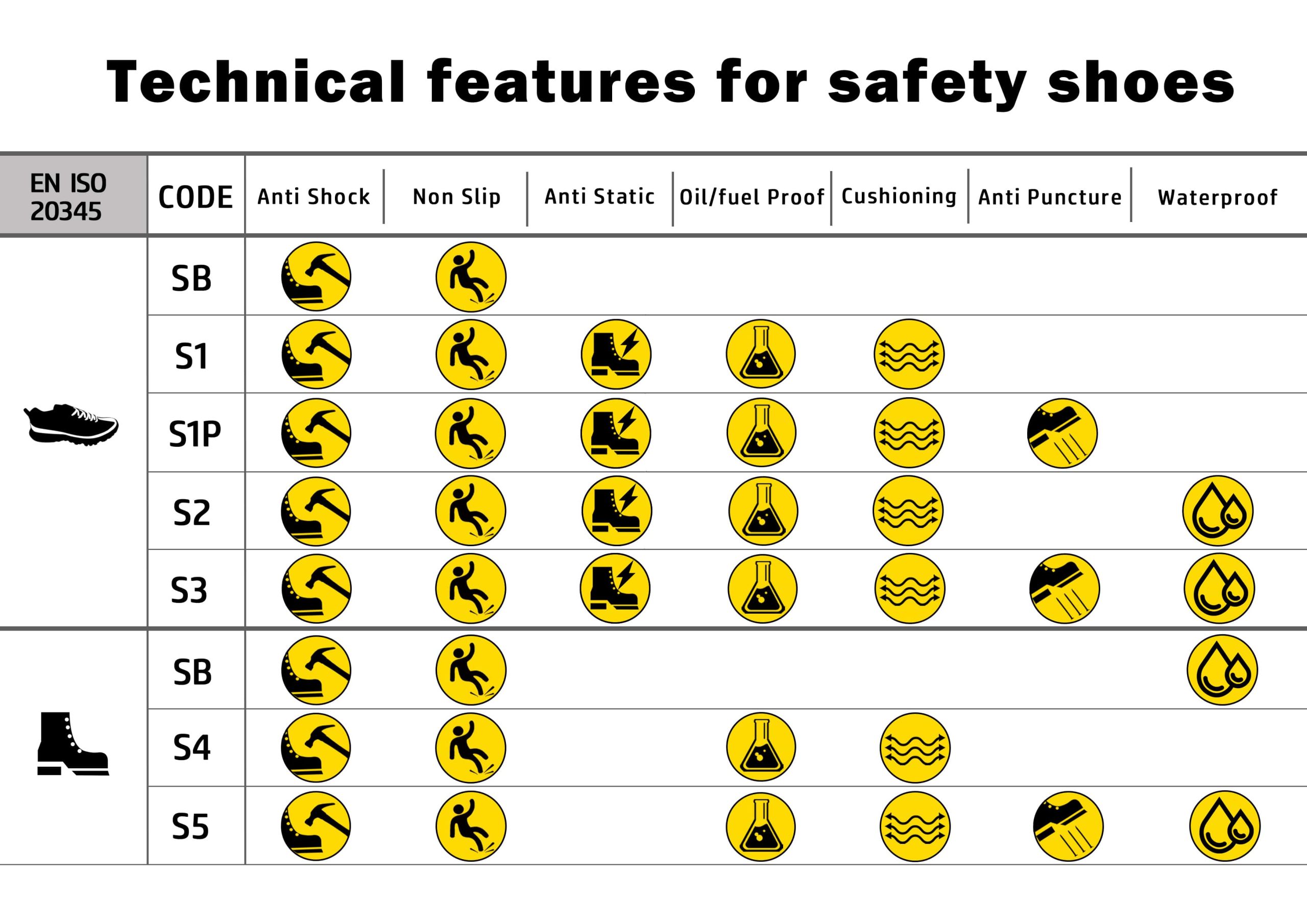

- Steel Toe Safety Shoes: In the oil and gas industry, pipes, tools, and other heavy objects can lead to foot injuries. Steel toe safety shoes provide excellent impact protection, safeguarding toes from pressure and impact injuries.

- Oil and Chemical Resistance: The oil and gas industry often involves various chemicals and oils, so the shoe’s outsole should exhibit excellent oil and chemical resistance. This helps prevent corrosion and damage to the shoes.

- Slip-Resistant Outsoles: Work environments in the oil and gas industry are often wet and slippery. Therefore, safety shoes should feature outstanding slip-resistant outsoles to ensure employees are less likely to slip on wet surfaces.

- Anti-Static Properties: Some oil and gas operations necessitate wearing anti-static shoes to prevent electric sparks that could cause explosions or fires. These safety shoes control and discharge static electricity.

- High-Temperature and Insulation: Some tasks in the oil and gas industry may involve high-temperature working conditions. Therefore, some safety shoes should have insulating properties to ensure the safety and comfort of employees in high-temperature environments.

Here are a few recommended safety shoes suitable for the oil and gas industry:

a. High-Quality Work Boots: These work boots typically feature steel toes, waterproof outsoles, and oil-resistant properties, making them suitable for various oil and gas environments.

b. Chemical-Resistant Boots: For tasks involving chemicals, these boots are often made from special materials with excellent chemical resistance.

c. Anti-Static Boots: Provide additional protection for workers who require anti-static properties to ensure safety in potentially explosive environments.

d. Heat-Resistant Boots: For high-temperature working conditions, these boots provide insulation to protect feet from high temperatures.

When selecting safety shoes for the oil and gas industry, consider the work environment and specific needs of employees. Ensure that the safety shoes comply with relevant regulations and standards and provide adequate protection while maintaining employee comfort and safety. Provide proper training to ensure employees know how to wear and maintain their safety shoes correctly. This will help reduce workplace accidents, enhance work efficiency, and protect employee health.

If you want to know more about safety shoes, please feel free to contact us.

We will wholeheartedly provide you with professional advice and high-quality safety shoes products.

Email: inquiry@eternitysafety.com

Whatsapp: +86 185 6150 1176