Safety Shoes Suitable for the Manufacturing Industry

NEWS

ENTESAFETY

Safety Shoes Suitable for the Manufacturing Industry

Workers working in the manufacturing industry face various potential hazards, and it is crucial to choose appropriate safety shoes to ensure their safety and comfort during the work process. This article will recommend some safety shoes specifically designed for the manufacturing industry to meet the needs of production line workers.

Wear and oil resistant safety boots

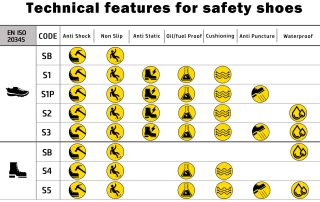

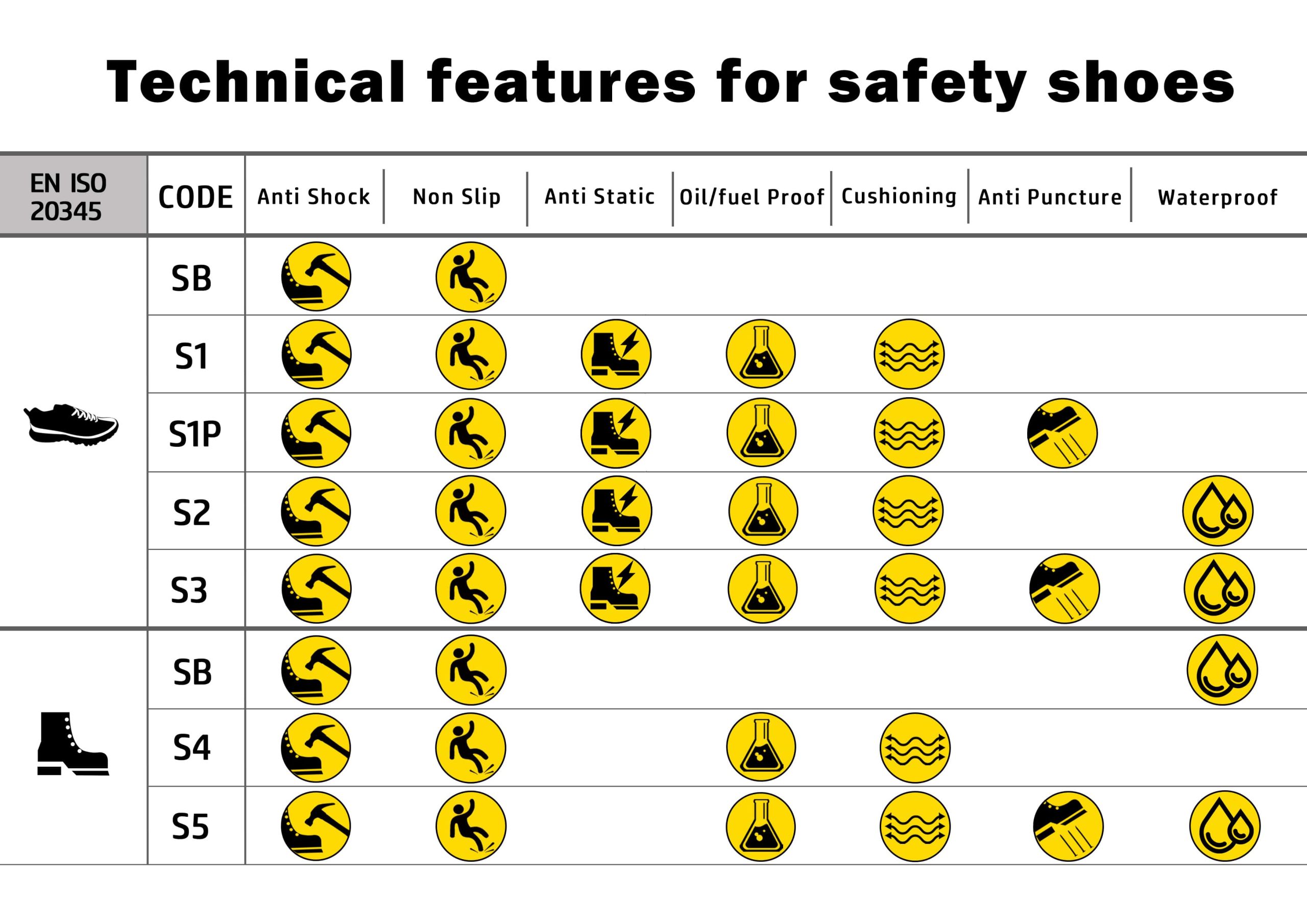

In the working environment of the manufacturing industry, the ground may be contaminated by machine oil, chemicals, etc. Therefore, it is crucial to choose safety boots with wear-resistant and oil resistant characteristics. This helps to provide better grip and ground stability.

Anti collision and anti puncture safety shoes

In the manufacturing industry, there is a higher risk of foot collisions and punctures. Choose safety shoes with collision and puncture resistant designs, such as steel toe and puncture resistant soles, to provide comprehensive foot protection.

Anti slip safety shoes

There may be lubricants or liquids on the production line, so choosing anti slip safety shoes is crucial. This helps to reduce the risk of workers slipping on slippery surfaces and ensure the safety of the work environment.

High temperature resistant safety boots

For workers working in high-temperature environments, it is necessary to choose heat-resistant safety boots. These boots are usually made of high-temperature resistant materials to protect workers from the scorching heat of the high-temperature surface.

Anti static safety shoes

In the field of electronic manufacturing, static electricity may cause damage to products. Choosing anti-static safety shoes can effectively prevent the generation of static electricity and ensure the safety of workers and equipment.

Comfortable and breathable design

In addition to safety, comfort is also a key factor. Choose breathable safety shoes to ensure workers keep their feet comfortable and dry during prolonged work.

Safety shoes that meet standard certification

Ensure that the selected safety shoes comply with relevant safety standards and certifications, such as ASTM standards, to ensure their reliability and safety in hazardous environments.

If you want to know more about safety shoes, please feel free to contact us.

We will wholeheartedly provide you with professional advice and high-quality safety shoes products.

Email: inquiry@eternitysafety.com

Whatsapp: +86 185 6150 1176